- HOME

- ABOUT US

- PRODUCTS

- Inkjet Printer

- Manual Screen Printing Machine

- Post-press Equipment

- Pre-Press Equipment

- Inkjet Printing Material

- Automatic Screen Printing Machine

- Squeegee

- Screen frames

- Heat Press Machine

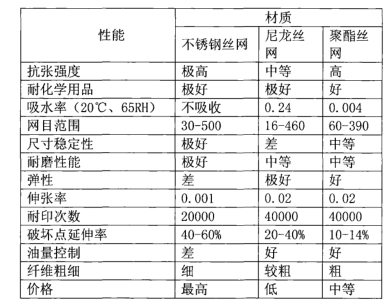

- Polyester mesh

- Handle Squeegee Holder

- Screen printing accessories

- frame adhesive

- hinge clamp

- Mesh Tension Stretcher

- tension meter

- emulsion scoop

- emulsion remover powder

- Photo Emulsion

- ink spatulas

- inkjet film

- Manual screen printing head

- screen printing spot gun

- screen printing hot gun

- T Iron

- Wooden/aluminum sleeve plate

- Ink Recycle Knife

- Squeegee scissors

- Plastic handle

- NEWS

- VIDEO

- CONTACT US

+86-18631122850

+86-18631122850

You are here:

You are here: